Introduction

Ongoing advancements in artificial intelligence, robotics, and augmented reality are redefining how manufacturing industry works. Augmented reality is an innovative combination of digital and audiovisual elements. This merging of physical elements with imaginative visuals leads to enhanced visualization of our surroundings. Manufacturers are using AR to simplify and speed up the production and manufacturing processes through immersive techniques.

What is AR manufacturing and what are its latest market stats?

In manufacturing sector, AR is being implemented to optimize and streamline product manufacturing and assembly through immersive techniques. As manufacturing requires precise detailing, implementing AR not only reduces the risk of errors but also improves quality control. AR-guided immersive training lets employees view real-time data, instructions, and guidance directly in their field of vision.

According to a recent report by ABI Research, shipments of AR smart glasses in the manufacturing sector are projected to hit $27 million by 2025. This shows the future of manufacturing revolves around augmented technologies to enhance efficiency and boost revenues.

Top 7 Applications of AR in Manufacturing

AR-enhanced designing and prototyping

AR tools and techniques help manufacturers design, visualize, and create products in real-world contexts. By overlaying digital elements on physical objects, designers can create realistic prototypes of products.

For example, aviation sector uses AR to create 3D models of aircraft components. This helps engineers assess design and make changes without any physical prototypes. Virtual designing and prototyping not only saves time but also reduces costs, leading to more efficiency in limited resources.

3D product visualization

Source: cdsvisual

Manufacturers can use AR to create interactive 3D models of products. Using AR-powered smart glasses and heads-up displays (HUDs), technicians can visualize relevant product data including equipment specifications, maintenance procedures, and troubleshooting guidelines superimposed on 3D models. This helps them accurately diagnose any errors in the design, streamline maintenance, and reduce repair times.

For example, AR headset can be used to view 3D product models created through CAD designs. This helps workers to interact with models in a realistic environment and understand exact requirements. The real-time display of product data also highlights any problems directly on the model. AR helps them collaborate and modify designs in real-time to optimize the final outcomes.

Training and upskilling

Source: softwebsolutions

AR can enhance training and upskilling of workers through AR-powered immersive simulations. Employees can practice complex manufacturing and assembly-related tasks in virtual environments which would not be possible otherwise. Experts around the world can train employees about latest industry trends through 3D AR Annotations of complex machines, digital manuals, step-by-step SOPs, and guides.

For example, using Microsoft Hololens, employees can quickly learn complex manufacturing tasks and collaborate with experts to get real-time guidance. This improves efficiency of workflow and improves quality by reducing errors.

Remote assistance and collaboration

Source: softwebsolutions

Using AR tools, workers can collaborate with their on-site and off-site teams to get real-time instructions through virtual overlays. This leads to better first-time fix rates, reducing downtime and travel needs for technicians. For example, Siemens uses AR glasses to enhance collaboration between field technicians and remote experts. This immersive collaboration removes all physical barriers and improves work efficiency significantly.

AR-guided assembly instructions

Source: linkedin

AR improves assembly lines by overlaying digital instructions, assembly steps, and quality checks directly on workstations. This helps employees follow clear, step-by-step guidance in their field of view, which leads to consistent product assembly and reduces the chances of errors.

Real-time maintenance and troubleshooting

Source: manwinwin

In manufacturing, equipment breakdowns can cause costly downtime and inefficiencies. Therefore, proper maintenance and real-time troubleshooting are necessary to minimize production losses. AR integration can help deal with troubleshooting issues and enhance daily productivity. Using AR, operators and maintenance staff can quickly identify and resolve issues within the system through real-time guidance.

Quality control and inspection

Source: metrology.news

AR integration can enhance real-time inspection and quality control in manufacturing process. It can help prevent defects, streamline production, and speed up time to market. For example, technicians using AR glasses can inspect products and receive real-time data from IoT sensors in the components, which notify them of any existing problems. In this way, AR can boost operational efficiency and increase productivity in manufacturing sector.

Benefits of AR in manufacturing

Enhanced operational efficiency

AR helps employees complete their tasks more effectively and accurately by offering real-time guidance and instructions. Moreover, creating and using digital work instructions is simple. Workers can use AR-powered devices to access these digital guides, schematics, and other important information, which removes the necessity for paper manuals.

Increased worker engagement

As AR is a relatively new technology, its immersive 3D experience and the opportunity to learn through virtual practices are still fresh for workers. Immersive experiences increase excitement and learning curiosity of workers. This increases worker engagement with their tasks, improves their morale, and reduces turnover rates.

Reduced costs

Integrating AR tools and techniques can reduce travel expenses, accommodation costs for experts, and fees for their on-site visits. It also reduces costs associated with unplanned downtimes through regular maintenance and internal audits. Moreover, AR eliminates the expensive trial-and-error phase which helps manufacturing companies to achieve financial growth quickly.

Improved worker safety

AR not just replaces real equipment and people; it also creates a safe learning space for workers to practice tasks virtually without risk. This enhances safety, training, and workflow. Moreover, AR can boost safety in manufacturing process by providing real-time alerts about any possible dangers. For example, it can warn workers when they enter hazardous areas or handle dangerous materials so they can avoid harmful accidents.

Logistics and Warehouse Management

AR technology improves logistics and warehouse management by providing visual navigation, inventory tracking, and order-picking assistance. Using AR-powered devices, warehouse staff can follow optimized routes, view real-time inventory information, and streamline order fulfillment. This reduces errors, shortens search times, and enhances inventory accuracy which leads to more efficient logistics and smoother warehouse operations.

Successful implementation cases of AR in manufacturing

TATA

TATA recently teamed up with Swedish industrial tool manufacturers in two assembly plants. The primary aim of this collaboration was to create a seamless solution that brings transparency across their supply chain. This system connects with ERP and logistics tools. Key features that increased worker efficiency by 30% include managing orders, kitting, electronic Kanban, digital work instructions, and real-time updates on dashboards. They also reduce the assembly process time from 3 days to just 4 hours.

BMW

Source: press.bmwgroup

BMW used AR glasses for its Munich plant workers to speed up inventory checks and reduce errors and inefficiencies. The results of using AR glasses were quite impressive. It decreased inventory identification time by 22% and error rate by 33%. So, while AR industrial solutions can cost a lot upfront, they’ll pay off for your business over time.

Porsche

Source: carscoops

Porsche has started using AGVs (automated guided vehicles) in its assembly process for the Taycan, its electric model. The auto company uses these AGVs to move cars between assembly stations and has adopted an automated production line setup. This means if a car needs installation of any interior parts, it can exit the main assembly line and move to the area where workers can customize it. This AGV-based production line helps Porsche save 30-40% on capital expenses compared to the traditional main line.

Samsung

Samsung is using 3D vision scanning to meet rising demands and quality standards for LCD panels. The company uses 3D scanner-based automated inspections that reduce inspection time to under 1 second per screen. This 3D scanning system has replaced manual processes and detects internal and surface defects very quickly. Moreover, it also boosts production line output, removes bottlenecks in inspection, and improves customer satisfaction.

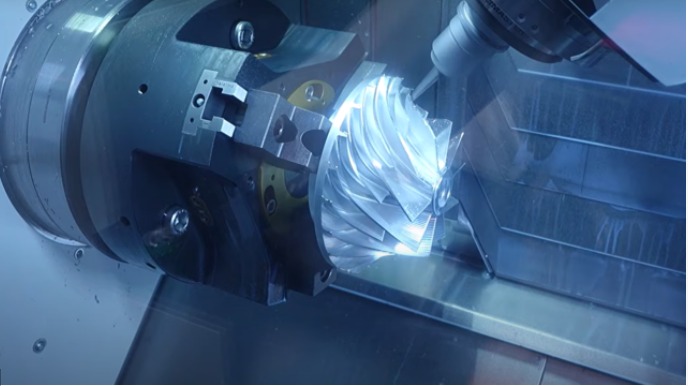

Martin-Baker

Source: mtdcnc

DMG Mori has made a collaboration with Martin-Baker to achieve 80% efficiency in overall equipment effectiveness (OEE). Their automation and software solution helped the company monitor and detect tool wear and related blockages. The system adjusts job orders and alerts the main control room about any failures. This keeps everyone aware of progress in production process. This setup quickly identifies and fixes machine issues with on-the-spot help and teamwork.

Future trends of AR implementation in manufacturing

Augmented reality has a growing influence on technology, with multiple software and hardware breakthroughs announced each year. The future of augmented reality has a strong connection to artificial intelligence. Digital work instructions combine the visual guidance of AR with the real-time insights of artificial intelligence. This provides huge benefits for critical jobs such as quality inspection where missed errors can lead to safety issues for customers

Conclusion

Augmented reality is one of the most widely used technology for manufacturing across the globe. Experts predict that “By 2025…industrial AR will reach a market value of $70 billion.” The teamwork between humans and machines opens up new ways to connect our factories and interact with data.

E-commerce businesses can employ AR-powered solutions to train workers, standardize processes, improve efficiency, and boost overall worker safety. Kivisense is a sino-french venture that provides industry-leading AR, VR, and AI-powered marketing solutions for e-commerce businesses. You can get in touch with us to start your augmented reality journey now.